What are the loads acting on a chassis frame, so that the vehicle can be constructed according to the loads?

In the present scenario, the automotive industry has been one of the rapid growing industries and is facing heavy competition from the competitors. This necessitates the need to work on various functional aspects of the automobile, starting from chassis design to aesthetic design.

The chassis acts as a skeleton on which, the engine, wheels, axle assemblies, brakes, suspensions etc. are mounted. The chassis receives the reaction forces of the wheels during acceleration and braking and also absorbs aerodynamic wind forces and road shocks through the suspension. So the chassis should be engineered and built to maximize payload capability and to provide versatility, durability as well as adequate performance.

All real physical structures, when subjected to loads or displacements, behave dynamically. The additional inertia forces, according to Newton’s second law, are equal to the mass times the acceleration. If the loads or displacements are applied very slowly, then the inertia forces can be neglected and a static load analysis can be justified, but in reality the loads are dynamic in nature.

Role of Chassis in Automotive - Continuing Importance of Chassis Engineering

Every vehicle body consists of two parts; chassis and bodywork or superstructure. The chassis is the framework of any vehicle. Its principal function is to safely carry the maximum load for all designed operating conditions. It must also absorb engine and drive line torque, endure shock loading and accommodate twisting on uneven road surfaces. The chassis receives the reaction forces of the wheels during acceleration and braking and also absorbs aerodynamic wind forces and road shocks through the suspension. So the chassis should be engineered and built to maximize payload capability and to provide versatility, durability as well as adequate performance.

To achieve a satisfactory performance, the construction of a heavy vehicle chassis is the result of careful design and rigorous testing. It should be noted that this ‘ladder’ type of frame construction is designed to offer good downward support for the body and payload and at the same time provide torsional flexibility, mainly in the region between the gearbox cross member and the cross member ahead of the rear suspension. This chassis flexing is necessary because a rigid frame is more likely to fail than a flexible one that can ‘weave’ when the vehicle is exposed to arduous conditions.

A torsionally flexible frame also has the advantage of decreasing the suspension loading when the vehicle is on uneven surfaces. The chassis which is made of pressed steel members can be considered structurally as grillages. It acts as a skeleton on which, the engine, wheels, axle assemblies, brakes, suspensions etc. are mounted. The frame and cross members form an important part of the chassis. The frame supports the cab, engine transmission, axles and various other components.

Cross members are also used for vehicle component mounting, and protecting the wires and tubing that are routed from one side of the vehicle to the other. The cross members control axial rotation and longitudinal motion of the main frame, and reduce torsion stress transmitted from one rail to the other.

Definition of Frame

Frame is a under carriage or structure that supports the engine and cab (body) of the automobile. It is made up of long two members called side members riveted together with the help of number of cross members.

Design Loads Acting over the Automobile Frame

1. Weight of the vehicle and the passengers, which causes vertical bending (STATIC LOADS - Loads due to chassis parts) of the side members.

2. Vertical loads when the vehicle comes across a bump or hollow (SHORT DURATION LOAD), which results in longitudinal torsion due to one wheel lifted with other wheels at the usual road level.

3. Loads due to road camber, side wind, cornering force (MOMENTARY DURATION LOAD) while taking a turn, which result in lateral bending off side members.

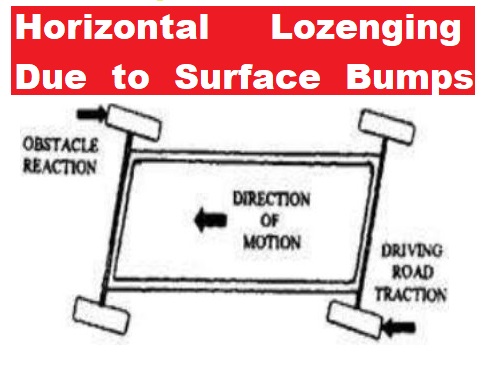

4. Load due to wheel impact with road obstacles may cause that particular wheel to remain obstructed while the other wheel tends to move forward , distorting the frame to parallelogram shape.

5. Engine torque and braking (INERTIA LOAD - while applying brakes) torque tending to bend the side members in the vertical plane.

6. Sudden IMPACT LOADS during a collision, which may results in a general collapse.

Design Considerations for Automobile Chassis for Prevention of Rolling over of a Vehicle

The chassis generally experiences four major loading situations that include:

1. Vertical Bending (Symmetric)

2. Longitudinal Torsion (Asymmetric vertical loads)

3. Lateral Bending

4. Horizontal Lozenging

Vertical Bending

Considering a chassis frame is supported at its ends by the wheel axles and a weight equivalent to the vehicle's loads, passengers and luggage is concentrated around the middle of its wheelbase, then the side members are subjected to vertical bending causing them to sag in the central region.

Longitudinal Torsion

When diagonally opposite front and rear road wheels roll over bumps simultaneously, the two ends of the chassis are twisted in opposite directions so that both the side and the cross members are subjected to longitudinal torsion which distorts the chassis.

Lateral Bending

The chassis is exposed to lateral side forces that may be due to the camber of the road, side wind, centrifugal force while turning a corner, or collision with some object. The adhesion reaction of the road wheel tyres opposes these lateral forces. As a net result a bending moment acts on the chassis side members so that the chassis frame tends to bow in the direction of the force.

Horizontal Lozenging

A chassis frame if driven forward or backwards is continuously subjected to wheel impact with road obstacles such as pot holes, road joints, surface humps, and curbs while other wheels produce the propelling thrust. These conditions cause the rectangular chassis frame to distort to a parallelogram shape, known as 'lozenging'.

No comments:

Post a Comment